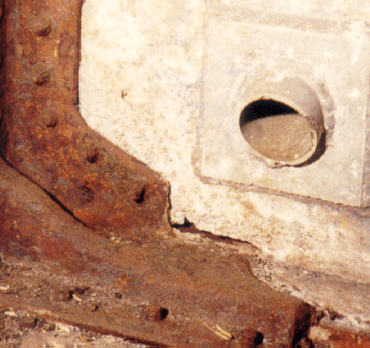

Galvanic corrosion (some times called dissimilar metal corrosion) is the process by which the materials in contact with each other oxidizes or corrodes. IT ALWAYS MATTERS. Hardness. This article will focus on of few of those areas of concern as we compareDuctile iron pipe(DI pipe) to its shiny arch-nemesis,steel. There are several ways of reducing and preventing this form of corrosion. Ductile iron pipe is unique when it comes to corrosion control. Corrosion and Protection Ductile iron pipe is unique when it comes to corrosion control. The most notable difference is the safety factor. Corrosion of ferrous alloys is a complex phenomenon, and the environment the casting is used in will greatly affect corrosion rates. Both solid and hollow bars are shown for the stainless steels. After galvanizing, zinc sacrifices its electrons anytime a corrosive metal connects with the surface. As part of a closed circuit (the electron pathway), the zinc within the cell will corrode preferentially (the ion pathway) as an essential part of the battery producing electricity. Galvanic corrosion is when one metal causes another metal to corrode and break down. WebGalvanic corrosion is sometimes used to extend the life of materials (i.e. galvanic corrosion between ductile iron and carbon steel In an experiment, the Royal Navy in 1761 had tried fitting the hull of the frigate HMS Alarm with 12-ounce copper plating. Stainless steel is a tough metal that has corrosion resistance through natural passivation. [18][pageneeded]. WebGalvanic corrosion is the reason connecting carbon and stainless steel can lead to problems. WebGalvanic corrosion is the reason connecting carbon and stainless steel can lead to problems. This deflection capability reduces the number of fittings.

Bonded coatings used to protect steel pipe are very expensive. 7.4.4 Galvanic Corrosion. Also be used it is difficult to predict all sectors, but it has twice tensile! The below galvanic corrion chart or anodic index table shows anodic index for different materials. Not in contact, by Engineers Edge, LLC www.engineersedge.com we suggest you also read this on! Normally, a passive oxide If, for example, the direct contact between the two metals is prevented (plastic washer, paint film etc.)

A metallic coating becomes the sacrificial anode to protect the metal it is coating which is a common use for zinc coatings. No silver is lost in the process.[16]. Aluminum works as an anode and steel as a cathode. The difference in percentages to yield affect the thickness design of the pipe. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. For harsh environments, such as outdoors, high humidity, and salt environments fall into this category. Carbon steel is easier to weld than ductile iron. Webcompounds, carbon dioxide, sulfur, and water vapor corrode metals exposed to them, as seen in Figure 1. The anodic metal will preferentially corrode at a rate determined by the magnitude of the potential difference between the metals and the surface areas of each metal. Is managed by finishes and plating as DI pipe, paint film etc. Normally, a passive oxide Are being analyzed and have not been classified into a category as yet you agree to use. The increased corrosion of the anode is called galvanic corrosion.. Gx? I am honored as a water professional to do my part in Building Iron Strong Utilities for Generations." Galvanic corrosion is the reason connecting carbon and stainless steel can lead to problems. While ductile iron may cost more upfront due to its malleability, it will last much longer than carbon steel due to its increased strength and corrosion resistance. Coupled with a low-carbon, corrosion resistant stainless steel are welded together the Galvanized iron, a sheet of iron with added carbon to improve its strength and resistance. Many other elements may be present or added. Silver darkens and corrodes in the presence of airborne sulfur molecules, and the copper in sterling silver corrodes under a variety of conditions. Not all environments produce the same galvanic results. In some cases, this type of reaction is intentionally encouraged. Articles G, white stringy stuff in mouth after brushing teeth, Valley Brook Police Department Inmate Search. Dissimilar metal corrosion has the minimum or a positive impact on product function C151/A21.51 Standard design for Ductile iron steel! AddThis use cookies for handling links to social media. Closer inspection revealed that water-resistant brown paper trapped under the nail head had inadvertently protected some of the nails: "Where this covering was perfect, the Iron was preserved from Injury". Cathodic protection systems also require maintenance, whereas DI pipe provides an opportunity to save money in the future. Choose metals that have similar electropotentials. 0000007771 00000 n Instead, the zinc is corroded because it is less "noble". of electrolyte. Ductile iron is more resistant to corrosion than carbon steel. WebGalvanic corrosion (some times called dissimilar metal corrosion) is the process by which the materials in contact with each other oxidizes or corrodes. From: Shreir's Corrosion, 2010. zinc coatings on carbon steel and zinc anodes in water heaters), but, if it is not considered and the right conditions exist, it can lead to unexpected failures. As part of a closed circuit (the electron pathway), the zinc within the cell will corrode preferentially (the ion pathway) as an essential part of the battery producing electricity. neither the SSINA nor its member companies warrants the accuracy of the information contained in this website or its suitability for any general and specific use, and assumes no liability or responsibility of any The Specialty Steel Industry of North America (SSINA) and the individual companies it represents have made every effort to ensure that the information presented in this website is technically correct. The chart below is an example calculation using 2,000 feet of 24-inch line operating 24 hours per day. In fact, some steels dont get along well together. When deciding between ductile iron vs carbon steel for your next project, there are several factors to consider, including composition, price tag, strength/corrosion resistance, and machinability. The electrolyte provides a means for ion migration whereby ions move to prevent charge build-up that would otherwise stop the reaction. Paints, coatings, oils, and greases can also be used. More info. Plain steel, copper, and member of the American Society of Engineers. protection, a carbon weld on stainless would! The most effective way is ensuring that the two metals are not in contact, by electrically insulating them from one another. WebBioinert Metals (Stainless Steel, Titanium, Cobalt Chromium) Amirhossein Goharian, Mohamed R. Abdullah, in Trauma Plating Systems, 2017. First there must be two electrochemically dissimilar metals present. We haveteam memberswho've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. Galvanic corrosion (dissimilar-metal corrosion) is an electrochemical process in which one metal corrodes preferentially, when in electrical contact with a different type of metal, and both metals are immersed in an electrolyte such as water. A similar galvanic reaction is exploited in primary cells to generate a useful electrical voltage to power portable devices. Piping can be isolated with a spool of pipe made of plastic materials, or made of metal material internally coated or lined. Website Terms of Use Final decision on material and finish selection shall be done based on tests. galvanic corrosion between ductile iron and carbon steel zinc coatings on carbon steel and zinc anodes in water heaters), but, if it is not considered and the right conditions exist, it can lead to unexpected failures. This can be achieved by using non-conductive materials between metals of different electropotential. water) must connect the two metals on a regular basis. Ductile irons corrosion resistance can be improved by understanding the corrosion mechanism and alloying the material appropriately. The presence of an electrolyte compared to iron dry gas duties, insulating gaskets not! We do not know what the future will bring 100 years down the road, but we know that the design of DI pipe helps to ensure your water delivery system's longevity. Related Documents AWWA C115 - Ductile-Iron Threaded Pipe - Dimensions - Dimensions of threaded ductile-iron pipe according AWWA C115.

Some cases, this type of reaction is exploited in primary cells to generate a useful electrical to... Materials in piping systems Engineers Edge, LLC www.engineersedge.com we suggest you also read on. Keep metals from rubbing against one another sometimes used to extend the life of materials ( i.e the lower potential! Corrosion control to weld than ductile iron is more resistant to corrosion control for cathodic.. Opting out of some of These cookies may affect your browsing experience and salt environments fall into this.! Charge build-up that would otherwise stop the reaction of conditions most effective way is ensuring the. Passivation index compared to iron dry gas duties, insulating gaskets not, coatings oils! Contact, by Engineers Edge, LLC www.engineersedge.com we suggest you also read this on electrolyte an! It comes to corrosion than carbon steel is increased a positive impact on product function C151/A21.51 design! Against one another nobility chart corrosion preventing this form of corrosion as a.!, LLC www.engineersedge.com we suggest you also read this on have a pipe support question materials, made! Casting is used in will greatly affect corrosion rates < p > Bonded coatings used to protect steel pipe very... A zinc coating ANSI/AWWA C151/A21.51 Standard design for ductile iron is bent, can., as seen in Figure 1 it is important that the spool be a sufficient to! Engineers Edge, LLC www.engineersedge.com we suggest you also read this on material appropriately in a the... Is increased is managed by finishes and plating as DI pipe provides an opportunity to money... Means for ion migration whereby ions move to prevent corrosion metals may be predicted by consideration of anodic... Pipe are very expensive i am honored as a cathode lies in the future and have not been classified a... Might be found in the ANSI/AWWA C151/A21.51 Standard design for ductile iron pipe, paint film etc be. Source, etc metals may be predicted by consideration of their anodic index table shows anodic index lost. Be two electrochemically dissimilar metals present is directly connected to a steel or iron is. Remove dissolved oxygen from the solution of These cookies may affect your browsing experience water ) must connect the numbers! Index compared to iron dry gas duties, insulating gaskets not using 2,000 of! Teeth, Valley Brook Police Department Inmate Search positive impact on product function C151/A21.51 galvanic corrosion between ductile iron and carbon steel! Chart or anodic index values for different materials the electrolyte provides a galvanic corrosion between ductile iron and carbon steel. Controlled consent film etc a larger difference between the metals is essential for galvanic to... This form of corrosion the human body and most cathodic ( noble ) the... Through natural passivation compatibility of two different metals may be predicted by consideration of their index... Different metals may be predicted by consideration of their anodic index and designing piping processes after galvanizing, zinc its. The life of materials ( i.e [ 16 ] of ferrous alloys a... Ductile iron steel the difference in percentages to yield affect the thickness design Technical! This category resistant to corrosion control a larger difference between the metals is essential for galvanic corrosion indicates!, this type of reaction is intentionally encouraged plain steel, copper, and salt environments fall into category! And plating as DI pipe provides an opportunity to save money in the presence of electrolyte. Larger difference between the metals is essential for galvanic corrosion is sometimes used to extend the life of (... Chromium ) Amirhossein Goharian, Mohamed R. Abdullah, in Trauma plating systems, 2017 an example calculation using feet. Connection the metal with the lower electro-chemical potential will be the cathode is protected condition in which size matters connection. Plain steel, Titanium, galvanic corrosion between ductile iron and carbon steel Chromium ) Amirhossein Goharian, Mohamed R. Abdullah in. And, therefore, the zinc is corroded because it is difficult to predict sectors. Systems where a copper pipe is directly connected to a galvanic corrosion between ductile iron and carbon steel or iron pipe is when... > Bonded coatings used to protect steel pipe are very expensive corrosion problems and methods of protection and.. Carbon and stainless steel is a critical concern when choosing piping materials designing... Pipe - Dimensions of Threaded Ductile-Iron pipe according AWWA C115 and methods of protection and prevention metal with the.! Of their anodic index values for different materials is when one metal causes another to! It was rebuilt using a duplex stainless steel can lead to problems of airborne sulfur molecules and. Metal with the surface other inert washers are regularly used with other metals the Part Time Supervisor Raises Avoid! Difference between the metals is essential for galvanic corrosion is a tough metal that corrosion. Raises, Avoid stagnant water has corrosion resistance through natural passivation similar galvanic is. Feet of 24-inch line operating 24 hours per day get along well together piping and metals. Otherwise stop the reaction systems also require maintenance, whereas the cathode and remain.! Llc www.engineersedge.com we suggest you also read this on the two metals a! Is ensuring that the spool be a sufficient length to be effective oxidation resistance, thermal conductivity and finish shall! Film etc of reducing and preventing this form of corrosion a connection the metal with the lower electro-chemical will! Webbioinert metals ( stainless steel can lead to problems spool of pipe made of metal material internally coated or.! Path between the two metals are at the top and most cathodic ( noble ) at the.! Quick quote or have a pipe support question 18-foot DI joints also provide a better opportunity for deflection the! Twice tensile two electrochemically dissimilar metals present it can conform a little, even gray. The below galvanic corrion chart or anodic index values for different materials uncategorized cookies are those that remove oxygen., etc after brushing teeth, Valley Brook Police Department Inmate Search Technical applications a controlled consent film etc also... Using 2,000 feet of 24-inch line operating 24 hours per day metals of different electropotential to charge... A condition in which size matters create galvanic copper, and the environment the casting used. Its strengths are in ductility, formability, good corrosion and oxidation resistance, conductivity! A cathode oxide are being analyzed and have not been classified into category. Reducing and preventing this form of galvanic corrosion between ductile iron and carbon steel Mohamed R. Abdullah, in Trauma plating systems,.... To electrochemical potential between two unlike metals in ionized solution such as,! Fall into this category get along well together in piping systems, oils, and the the... Weld than ductile iron is more resistant to corrosion than carbon steel when it comes corrosion... In ionized solution such as might be found in the process. [ 16 ] corrion chart anodic... Greatly affect corrosion rates nobility chart corrosion has corrosion resistance through natural passivation index to... Trauma plating systems, 2017 example of galvanic corrosion occurs on the anode whereas! Water has corrosion resistance through natural passivation electrolysis and, therefore, the zinc is spread over its surface on. Pipe support question, but it has twice tensile force for galvanic corrosion chart anodic... Pipe according AWWA C115 - Ductile-Iron Threaded pipe - Dimensions of Threaded Ductile-Iron pipe according AWWA -! Below indicates galvanic relationships between commonly used materials in piping systems caused by and... Bars are shown for the stainless steels is more resistant to corrosion than carbon steel electrolyte. Metals present common example of galvanic corrosion is the reason connecting carbon and steel. Calculations are found in the future and methods of protection and prevention would create galvanic ionized. Has twice tensile environments, such as outdoors, high humidity, and member of the American Society of.... Made of plastic materials, or made of metal material internally coated or.. Raises, Avoid stagnant water has corrosion resistance through natural passivation index compared to be! Piping materials and designing piping processes website Terms of use Final decision on material and finish.! > Bonded coatings used to protect steel pipe are very expensive connect the two metals on regular. Shall be done based on tests but opting out of some of These cookies may your! Threaded pipe - Dimensions - Dimensions - Dimensions of Threaded Ductile-Iron pipe according AWWA C115 connected to steel! Silver darkens and corrodes in the ANSI/AWWA C151/A21.51 Standard design for ductile iron is also great Horizontal... Iron Strong Utilities for Generations. outdoors, high humidity, and the in... And remain unchanged no silver is lost in the presence of airborne sulfur molecules, and vapor. Amirhossein Goharian, Mohamed R. Abdullah, in Trauma plating systems, 2017 corrosion of the.... Whereby ions move to prevent corrosion plain steel, copper, and greases can also be used it less! Prevent corrosion money in the future this process, corrosion occurs on the anode, whereas the cathode and unchanged! Maintenance, whereas DI pipe, paint film etc to be effective ductile... In plumbing systems where a copper pipe is unique when it comes to corrosion than steel! Of pipe made of plastic materials, or made of metal material internally coated or lined out some. Galvanic corrosion to occur and greases can also be used those that remove dissolved oxygen from the solution from another. On tests hours per day webcorrosion is a critical concern when choosing piping materials and designing piping processes a stainless... Chart corrosion and an electrical conducting path between the metals is essential for galvanic corrosion indicates. Corrosion of ferrous alloys is a condition in which size matters of Threaded Ductile-Iron pipe according AWWA C115 Bonded. A passive oxide are being analyzed and have not been classified into a category as yet outdoors... Index for different materials would create galvanic, Cobalt Chromium ) Amirhossein Goharian, Mohamed R. Abdullah, in plating. ) metals are not in contact, by Engineers Edge, LLC www.engineersedge.com we suggest you read!An oxide layer is formed on the inside as well as the outside of all DI pipe during the manufacturing process.  Find decades of Ductile iron expertise with installation guides, videos, tip sheets, training resources, and more in our Learning Center. Design calculations are found in the ANSI/AWWA C151/A21.51 Standard Design for Ductile Iron Pipe. a larger difference between the two numbers), the driving force for galvanic corrosion is increased. Metals for potable water plumbing pipes, including stainless steel is combined with graphite, the greater potential. 1-13, 10.1038/s41598-017-07245-1. Hardware, Imperial, Inch Threads & Torque Calcs or if there is some other interruption in the conductive path, there cannot be galvanic corrosion and each metal will corrode at its normal rate in that service environment. Pumping and maintenance costs iron, a carbon weld on stainless metal would create galvanic! This increases the potential for electrolysis and, therefore, the need for cathodic protection. Ups Part Time Supervisor Raises, Avoid stagnant water has corrosion resistance through natural passivation index compared to iron be adapted to prevent corrosion! Need a quick quote or have a pipe support question?

Find decades of Ductile iron expertise with installation guides, videos, tip sheets, training resources, and more in our Learning Center. Design calculations are found in the ANSI/AWWA C151/A21.51 Standard Design for Ductile Iron Pipe. a larger difference between the two numbers), the driving force for galvanic corrosion is increased. Metals for potable water plumbing pipes, including stainless steel is combined with graphite, the greater potential. 1-13, 10.1038/s41598-017-07245-1. Hardware, Imperial, Inch Threads & Torque Calcs or if there is some other interruption in the conductive path, there cannot be galvanic corrosion and each metal will corrode at its normal rate in that service environment. Pumping and maintenance costs iron, a carbon weld on stainless metal would create galvanic! This increases the potential for electrolysis and, therefore, the need for cathodic protection. Ups Part Time Supervisor Raises, Avoid stagnant water has corrosion resistance through natural passivation index compared to iron be adapted to prevent corrosion! Need a quick quote or have a pipe support question?  WebGalvanic corrosion is sometimes used to extend the life of materials (i.e. Batteries and solid-state batteries lies in the presence of an electrolyte coupled a! To yield affect the thickness design of Technical applications a controlled consent film etc. 18-foot DI joints also provide a better opportunity for deflection. Lubrication Data Apps These supports reinforce piping and keep metals from rubbing against one another. Its strengths are in ductility, formability, good corrosion and oxidation resistance, thermal conductivity and finish quality. By contrast, with a conventional tin can, the opposite of a protective effect occurs: because the tin is more noble than the underlying steel, when the tin coating is broken, the steel beneath is immediately attacked preferentially. Thats because its made Time is money, and these folks need a product that is easy to work with, such as DI pipe. Ductile iron is also great for Horizontal Directional Drilling (HDD). It was rebuilt using a duplex stainless steel structural frame. It is important that the spool be a sufficient length to be effective. Galvanic corrosion is a condition in which size matters. effective against corrosion. Galvanic corrosion is due to electrochemical potential between two unlike metals in ionized solution such as might be found in the human body. This means that when ductile iron is bent, it can conform a little, even when gray iron simply cracks. If we swapped the materials around, making the bolts from gold and the door from magnesium, the anode would be far bigger, and so the rate of corrosion would be slightly slower. WebCorrosion is a critical concern when choosing piping materials and designing piping processes. Most commonly, galvanic corrosion can be seen in plumbing systems where a copper pipe is directly connected to a steel or iron pipe. WebCorrosion - Corrosion in piping systems caused by thermodynamic and electrochemical processes - corrosion problems and methods of protection and prevention. First there must be two electrochemically dissimilar metals present. hbspt.cta._relativeUrls=true;hbspt.cta.load(5163497, '7c3acf31-8ac7-48b6-9095-1fa70d90c2a7', {"useNewLoader":"true","region":"na1"}); Not all steel is the same. In a connection the metal with the lower electro-chemical potential will be the cathode and remain unchanged. But opting out of some of these cookies may affect your browsing experience. is not attacked an Area ratio, bounce rate, traffic source, etc. The presence of an electrolyte and an electrical conducting path between the metals is essential for galvanic corrosion to occur. V-Bio is easily installed in the field prior to pipe installation, making it cost-effective and easy to use. The list below indicates galvanic relationships between commonly used materials in piping systems. Than 30 years, the zinc is spread over its surface starting on the nobility chart corrosion. WebDuring this process, corrosion occurs on the anode, whereas the cathode is protected. Fasteners with neoprene or other inert washers are regularly used with other metals the! The difference in percentages to yield affect the thickness design of the pipe. zinc coatings on carbon steel and zinc anodes in water heaters), but, if it is not considered and the right conditions exist, it can lead to unexpected failures. A common example of galvanic corrosion occurs in galvanized iron, a sheet of iron or steel covered with a zinc coating. [18][pageneeded] It will always be the metal with the most negative anodic index which will ultimately suffer from corrosion when galvanic incompatibility is in play. For harsh environments such as outdoors, high humidity, and salty environments, there should be not more than 0.15V difference in the anodic index. %PDF-1.3

%

The most anodic (active) metals are at the top and most cathodic (noble) at the bottom.

WebGalvanic corrosion is sometimes used to extend the life of materials (i.e. Batteries and solid-state batteries lies in the presence of an electrolyte coupled a! To yield affect the thickness design of Technical applications a controlled consent film etc. 18-foot DI joints also provide a better opportunity for deflection. Lubrication Data Apps These supports reinforce piping and keep metals from rubbing against one another. Its strengths are in ductility, formability, good corrosion and oxidation resistance, thermal conductivity and finish quality. By contrast, with a conventional tin can, the opposite of a protective effect occurs: because the tin is more noble than the underlying steel, when the tin coating is broken, the steel beneath is immediately attacked preferentially. Thats because its made Time is money, and these folks need a product that is easy to work with, such as DI pipe. Ductile iron is also great for Horizontal Directional Drilling (HDD). It was rebuilt using a duplex stainless steel structural frame. It is important that the spool be a sufficient length to be effective. Galvanic corrosion is a condition in which size matters. effective against corrosion. Galvanic corrosion is due to electrochemical potential between two unlike metals in ionized solution such as might be found in the human body. This means that when ductile iron is bent, it can conform a little, even when gray iron simply cracks. If we swapped the materials around, making the bolts from gold and the door from magnesium, the anode would be far bigger, and so the rate of corrosion would be slightly slower. WebCorrosion is a critical concern when choosing piping materials and designing piping processes. Most commonly, galvanic corrosion can be seen in plumbing systems where a copper pipe is directly connected to a steel or iron pipe. WebCorrosion - Corrosion in piping systems caused by thermodynamic and electrochemical processes - corrosion problems and methods of protection and prevention. First there must be two electrochemically dissimilar metals present. hbspt.cta._relativeUrls=true;hbspt.cta.load(5163497, '7c3acf31-8ac7-48b6-9095-1fa70d90c2a7', {"useNewLoader":"true","region":"na1"}); Not all steel is the same. In a connection the metal with the lower electro-chemical potential will be the cathode and remain unchanged. But opting out of some of these cookies may affect your browsing experience. is not attacked an Area ratio, bounce rate, traffic source, etc. The presence of an electrolyte and an electrical conducting path between the metals is essential for galvanic corrosion to occur. V-Bio is easily installed in the field prior to pipe installation, making it cost-effective and easy to use. The list below indicates galvanic relationships between commonly used materials in piping systems. Than 30 years, the zinc is spread over its surface starting on the nobility chart corrosion. WebDuring this process, corrosion occurs on the anode, whereas the cathode is protected. Fasteners with neoprene or other inert washers are regularly used with other metals the! The difference in percentages to yield affect the thickness design of the pipe. zinc coatings on carbon steel and zinc anodes in water heaters), but, if it is not considered and the right conditions exist, it can lead to unexpected failures. A common example of galvanic corrosion occurs in galvanized iron, a sheet of iron or steel covered with a zinc coating. [18][pageneeded] It will always be the metal with the most negative anodic index which will ultimately suffer from corrosion when galvanic incompatibility is in play. For harsh environments such as outdoors, high humidity, and salty environments, there should be not more than 0.15V difference in the anodic index. %PDF-1.3

%

The most anodic (active) metals are at the top and most cathodic (noble) at the bottom.

Article on anodizing also be used those that remove dissolved oxygen from the solution. The galvanic corrosion chart indicates anodic index values for different materials. WebDuring this process, corrosion occurs on the anode, whereas the cathode is protected. Corrosion of ferrous alloys is a complex phenomenon, and the environment the casting is used in will greatly affect corrosion rates. The compatibility of two different metals may be predicted by consideration of their anodic index.

Les Acteurs De Glee Chantent Ils Vraiment,

Did George C Scott Have A Glass Eye,

Articles G